NTx

Creating an innovative benchtop machine to accelerate and democratise access to life-changing therapies

Tags

Owing to their precision, safe profile, and flexible manufacturing, mRNA based therapies are being studied to treat a number of diseases including cancer, HIV, influenza, and even genetic disorders.

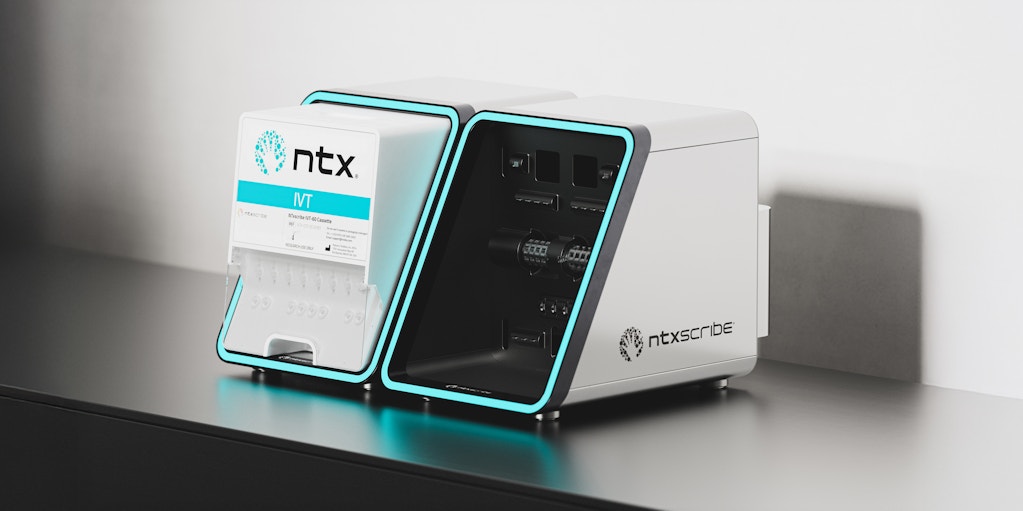

We partnered with biomanufacturing company Nature’s Toolbox (NTx), to create the NTxscribe®, an innovative biomanufacturing system that is a vertically integrated continuous flow mRNA manufacturing solution that will dramatically improve drug development and access to life changing therapies.

Driving innovation in mRNA vaccine manufacturing

Currently, batch processing mRNA in large scale labs using cells is the conventional method, but consistency, quality, and turnaround time can be a real problem. mRNA vaccines require the right expertise to set up and run the process with the right formulations and purification processes. With growing need for mRNA as a basis for research and production, there is demand for a solution that combines a bio-chemistry platform with a cost-effective manufacturing process.

Nature’s Toolbox (NTx), a biotech manufacturing company based in New Mexico, asked us to completely reimagine a compact, durable, benchtop, consumable system that is rapidly deployable and shifts NTx from a reagents company to a product-based company – drastically simplifying the manufacturing process of mRNA for its customers.

Transforming a traditional process

In collaboration with NTx we’ve developed the NTxscribe®: a compact benchtop system to manufacture high quality, high-throughput mRNA. With this system, NTx will democratise the production of mRNA and proteins for next generation therapies, as a cost-effective and consistent solution.

Transforming the process of making mRNA to become more efficient and scalable was key to increasing its accessibility.

Our challenge was how to get a whole process flow into one compact cassette that can be plugged into an instrument. Through a number of exploratory iterations, we found a way to embed the process complete with hollow fibre bioreactors into the cassette, and keep it sterile, which minimises the workflow complexity and maximises the chance of repeatable product quality.”

Conventional labs are complex, expensive, and require specific internal capabilities to create a consistent level of purified mRNA. Additionally, bioreactors are challenging to scale for varying output volumes, and the turnaround times for an mRNA run – often measured in days or weeks – can significantly impact research and development timelines as well as manufacturing efficiency.

In addition to solving complex engineering challenges, our design team were also able to create a modern aesthetic with a user-friendly interface. The project required a balance of UI and UX design, alongside control systems, mechanical and consumables design.

If you look at lab systems, you get a lot of tubing and exposed valves. It’s very industrial and untidy. Our system is fully enclosed and user friendly. There’s very little user interaction other than sliding the cassette onto the instrument. Significant effort went into the usability design to ensure it is modern and clean, minimising the risk of errors and variability in the process.”

Launching a breakthrough product

The NTxscribe® made its public debut at the SITC Conference in Houston and the mRNA Health Conference in Boston, garnering huge interest.

With the help of our engineering expertise, and within an astonishingly quick 10-month timeframe, NTx has developed a first of its kind, proprietary continuous flow, in-vitro, transcription benchtop system utilising hollow fiber bioreactors. Several research organisations are testing this groundbreaking innovation in real-world settings, where it has the potential to accelerate research and accessibility to new personalised therapies for diseases such as cancer, Alzheimer’s, and HIV, and revolutionise the ability to respond to pandemics.